Bottle washing Machines

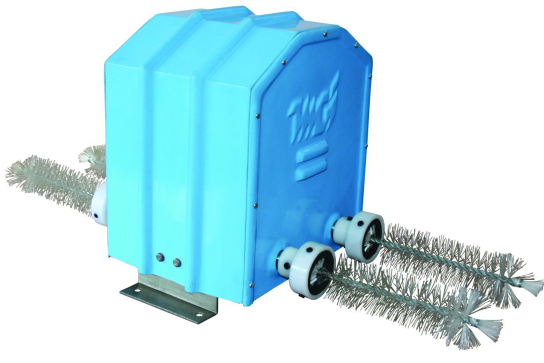

Brushing Unit with FRP / SS Cover – for Glass Bottles

- The Brushing unit is used for cleaning glass bottles.

- It is assembled on a stainless steel base plate with a Fiber Reinforced Plastic (FRP) SS cover.

- This cover protects a 1/2 HP I Phase 230 V 50 Hz motor. The motor is connected to two stainless steel shafts with pullies and V-belt.

- This unit must be mounted on the center of a cement / stainless steel/plastic tank of height 2.5 –3 feet. The size of the tank depends on the space availability and the number of bottles to be washed. The brushing unit thus mounted has two brushes extending on one side and two brushes on the other. Therefore two people standing on opposite sides of the tank can at once clean 4 bottles.

- Once the bottles are brought back from the market, they are soaked in another tank containing water with soap solution. This ensures that all dirt particles are loosened. The bottles are now ready to be brushed.

- There are two types of brushes mounted on the unit. One long brush cleans the inside of the bottles and at the same time another brush cleans the mouth of the bottle where there is generally rust formation due to crown corks. Two persons can wash approximately 8-12 bottles per minute. This depends on the dexterity of the workers and dirtiness of the bottles.

- After the brushing the bottles can be rinsed with plain water with the help of Rinser.

- The Maintenance of the machine consists of greasing, V belt tightening whenever required and general cleaning

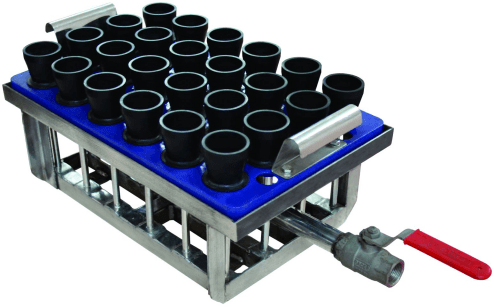

Rinser with 24 Cups – for Glass Bottles

This unit is meant for rinsing 24 glass bottles at a time. It can be fitted on top of a cement/plastic or SS Tank. It has 24 nozzles fitted on SS pipes and connected to a central pipe with ball valve which is connected to a water source like overhead tank or pump. All contact parts are SS 304.

24 Bottles are kept upside down in the rubber cups. When the ball valve is opened, water jets into the bottles and rinses them. The rinse water falls back into the tank below and can be drained or recycled as required. About 48 bottles can be washed in a minute depending on the speed of the operators.

The unit requires very little maintenance. Generally the rinser is meant for 200 ml/ 250 ml / 300 ml soda / soft drink bottles. But it can be altered to clean bottles of other shapes and sizes.

Rinser with 12 cups for PET Bottles

This unit is meant for rinsing 12 Glass bottles at a time. It can be fitted on top of a cement/plastic or SS Tank. It has 12 nozzles fitted on SS pipes and connected to a central pipe with ball valve which is connected to a water source like overhead tank or pump. All contact parts are SS 304.

This Rinser is mainly for bottles with large mouth diameters and larger sizes. Bottles of size 500 ml, 1000 ml etc for milk and other liquids can be rinsed. 12 Bottles are kept upside down in the nylon cups specially made to suit the mouths of the bottles. When the ball valve is opened, water jets into the bottles and rinses them. The rinse water falls back into the tank below and can be drained or recycled as required. About 24 bottles can be washed in a minute depending on the speed of the operators. The unit requires very little maintenance.

Rinser with 12 / 24 Cups with Pump & Tray for Glass Bottles

- The Motorized Rinser is ideal for high-speed jet rinsing of PET / Glass bottles.

- The pump must be used in case overhead tank is not available.

- The Rinser is mounted on a portable SS table with a water collection tray.

- A monoblock pump is provided to jet the water into the bottles.

- Water connection is made to the inlet of the pump.

- The outlet of the pump is connected to the three way ball valve of the Rinser.

- The bottles are kept upside down in the rubber cups.

- Ball valve is opened and the bottlesare rinsed.

- The rinsing water falls back into the collection tray and can be reused after filtration or drained.

- Once the rinsing is over, the three way ball valve can be closed to load the next lot.

- Meanwhile the pump is on and the pumped water is recycled back through the third port of the ball valve.

- About 24 / 48 bottles can be washed per minute depending on the speed of the operator.

Rinser with 2 Nozzles for Glass / PET Bottles Press Type with Pump

This rinser is ideal for quick high pressure jet rinsing of PET bottles with pressurized water. A ½ Hp I ph monoblock pump is fitted on the machine for this. It can be used for rinsing all Pet bottles from 200 ml to 2000 ml. It consists of a stand and tray on which the two nozzle rinser is fitted. The pump is installed below the tray. An NRV is fixed on the pipe line from pump to rinsers so that when the bottles are not rinsed, the water flows back to reservoir. So the pump can run continuously and need not be switched on and off.

The Rinser consists of two spring loaded nozzles. When two bottles are pressed upside down on the nozzles, the bottles are flushed with a jet of water. The rinse water falls back in to the tray below from where it can be drained or recycled as required.

The water collection tray, stand and rinser nozzles are all made of SS 304. About 12-14 bottles can be rinsed per minute – but this depends on the speed of the operators.

Semi Automatic Washing Machine with Brushing Unit & Rinser for Glass Bottles

- This is a compact washing machine for glass bottles.

- It consists of a Brushing unit mounted on one side of the machine. The unit has four brushes. An extra set of mouth cleaning brushes are also provided.

- Two persons can stand and wash two bottles each on either side of the machine.

- After Brushing bottles are kept upside down on the adjoining rinser trays. These trays can hold 24 bottles each

- Once the tray is full, it is manually pushed and it goes to the next position where the bottles are rinsed with high speed jets of water. For this a 1/2 HP I ph pump is provided. Two rinsers with two tanks and two pumps are provided.

- The machine can hold 7 trays in a row. The bottles are rinsed twice as they are pushed along the line.

- The rinsed water falls back into the tanks at the bottom and is recycled. The tanks can hold about 100 liters of water. They are provided with water inlet & outlet ball valves.

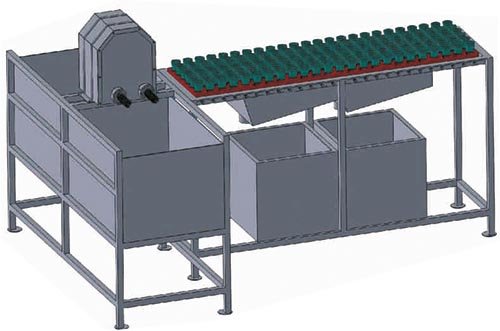

Semi Automatic Four Stage Washing Machine for Glass Bottles (Rinsing Type)

Automatic Bottle Washing machine has been designed and developed for washing 200ml/250ml/300ml soda/soft drink glass bottles. It can be altered / modified to wash bottles of other shapes and sizes also. The speed of the machine is 36 bottles per minute. An ideal compartmentalized machine, it has various wash stages. The machine is constructed of stainless steel, is robust and can withstand the rigours of continuous use. The unique design enables easy usage and maintenance.

A number of ABS (SS is optional) trays are provided. The trays are light weight and designed such that bottles need not be kept one by one. The Trays are directly overturned on to plastic crates containing the bottles. The bottles seat on the rubber cups on the trays. This filled tray is then kept at the inlet port of the machine. A pneumatic system pushes the trays into the machine at set time intervals.

The machine has four high speed jet washing stages. In each stage, the bottles are washed twice. Each stage has its own SS tank and 2 Hp III ph mono-block pump. The water is pumped into the two rinsers of each stage. The bottles are washed by two water jets – one from the bottom which washes inside and one from the top which washes from the outside. The rinsed water falls back into the tank at the bottom through a SS mesh provided on each tank where it is filtered. This mesh can be periodically removed and cleaned. The water in the tank can also be drained and refilled periodically. The first stage can be a caustic soda wash, the second stage a hot water wash and the third and fourth stages – plain water.

After washing the trays are ejected at the end of the machine from where they can be taken off and reloaded back into plastic crates by overturning them. A control panel is provided for switching on the machine, its pneumatic system and each of the four wash pumps. Each section of the machine is provided with acrylic windows where the washing can be seen.

The machine has the following advantages:

- The unique design of the machine enables easy dismantling, transportation and installation.

- Easy to use and maintain

- Two persons are enough for operating the machine.

- Even the dirtiest bottles come out sparkling clean.

- Bottles are washed on the inside as well as outside.

- The panels of the machine can be easily removed for inside cleaning or maintenance purpose

Technical Specifications:

Dimensions:

- 5500mm length x 1310mm, breadth x 1625mm height

- Total Horse Power: 8.5 HP Number of Trays: 24 nos.

20 Liter Single / Double Jar – Washing Machine

The Machine is available with one or two brushes to wash one or two 20 liter mineral water Cans at a time. It is fitted with a 1/2 Hp I ph motor which rotates the vertical brushes and a 1/2 HP I ph monoblock pump to jet water inside the Cans at the time of washing.

One or Two Cans are put upside down on the brushes. When a switch is pressed, the brushes rotate and at the same time the pump jets water into it. The Cans are thoroughly cleaned inside. The water that is jetting inside falls back into the collection tub below and can be disposed of as required. A water outlet is provided on the bottom of the tank for this. The pump and motor are fitted below the tank and are covered on three sides thus protecting them from water. The Brushes can be easily changed once they are worn out.

The machine is made out of SS 304 and is sturdy and suitable for continuous use. With a two brush machine about 4 Cans can be washed per minute and for a single brush machine about 2 Cans per minute